-

Home

-

Products

-

HOTFLOW 3/20

-

HOTFLOW 3/26 XL

-

Selective Welding System VERSAFLOW 3/45

-

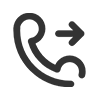

Full Tunnel Nitrogen Wave Soldering System POWERFLOW ULTRA

-

HR 600/2 Repair station

Learn more

-

InSPIre-630 Online High-Speed 3D Solder Paste Inspection System

-

S510 Online 2D Automatic Optical Inspection Equipment

-

A-630 Online 3D Automatic Optical Inspection Equipment

Learn more

-

X-ray Inspection Equipment AX9100MAX

-

Semiconductor Micro-Focus X-Ray Inspection Equipment AX8300S

-

Semiconductor Micro-Focus X-Ray Inspection Equipment AX8300Si

-

X-ray Inspection Equipment AX9100

-

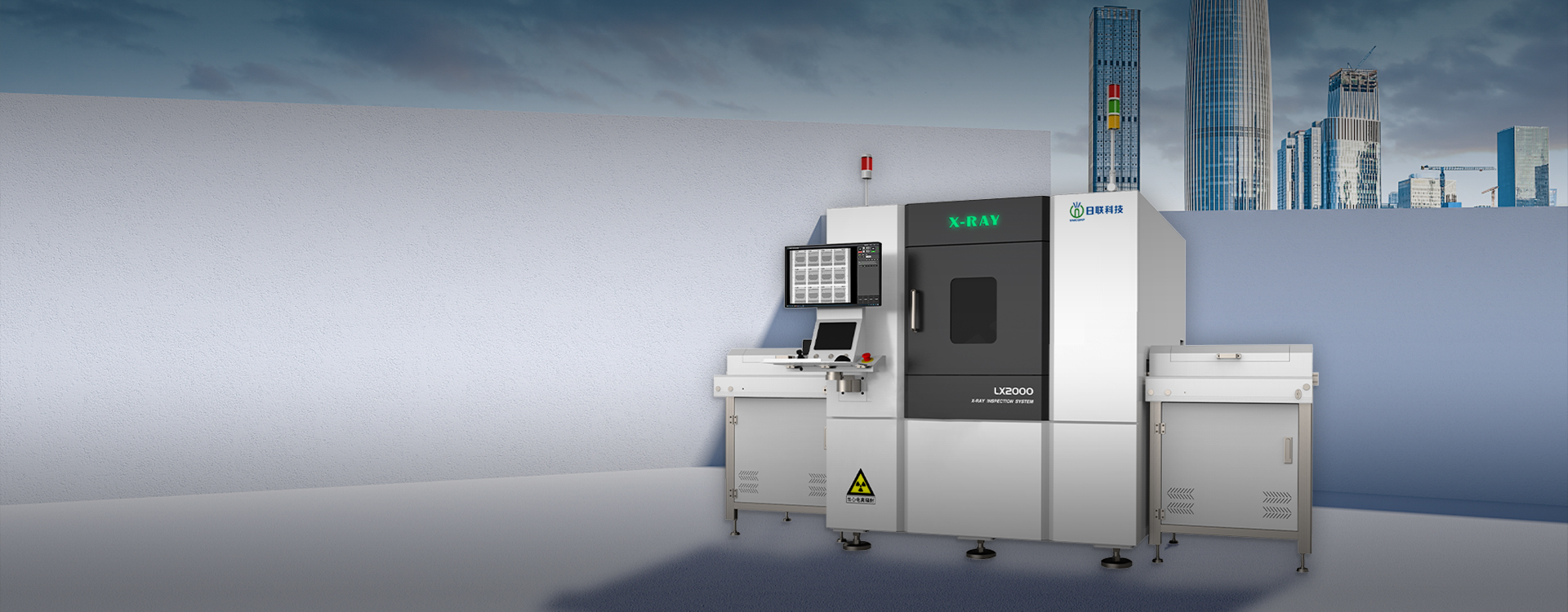

X-ray Online Inspection Equipment LX2000

-

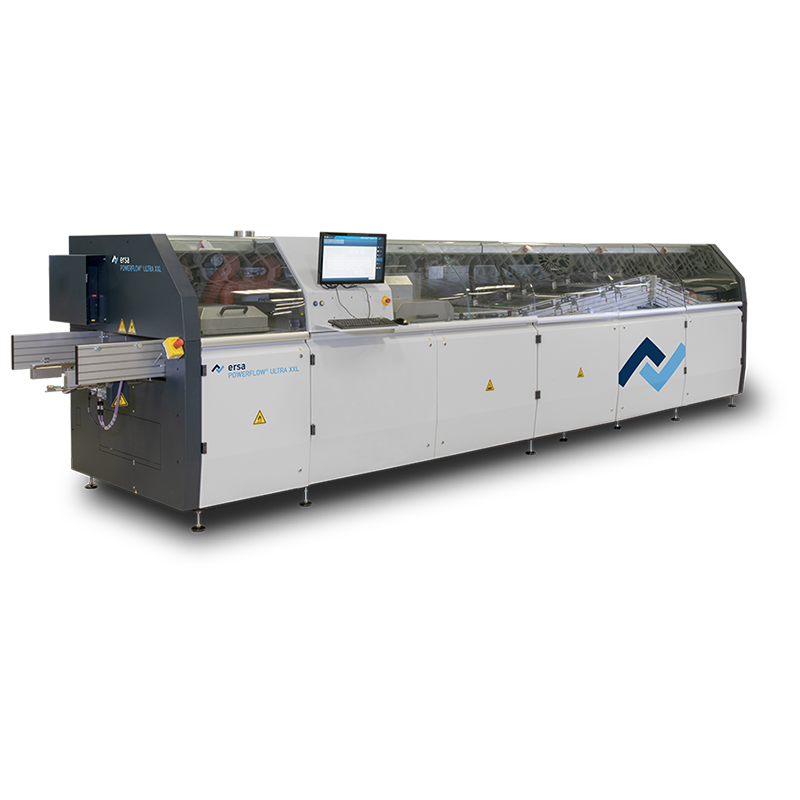

3D Online X-Ray Inspection Equipment LX9200

Learn more

-

Intelligent Nozzle Cleaning and Inspection All-in-One Machine

-

Fully Automatic Nozzle Cleaning Machine

-

Fully Pneumatic Stencil Cleaning Machine

Learn more

-

Single Wafer Coater

-

Single wafer cleaning machine

-

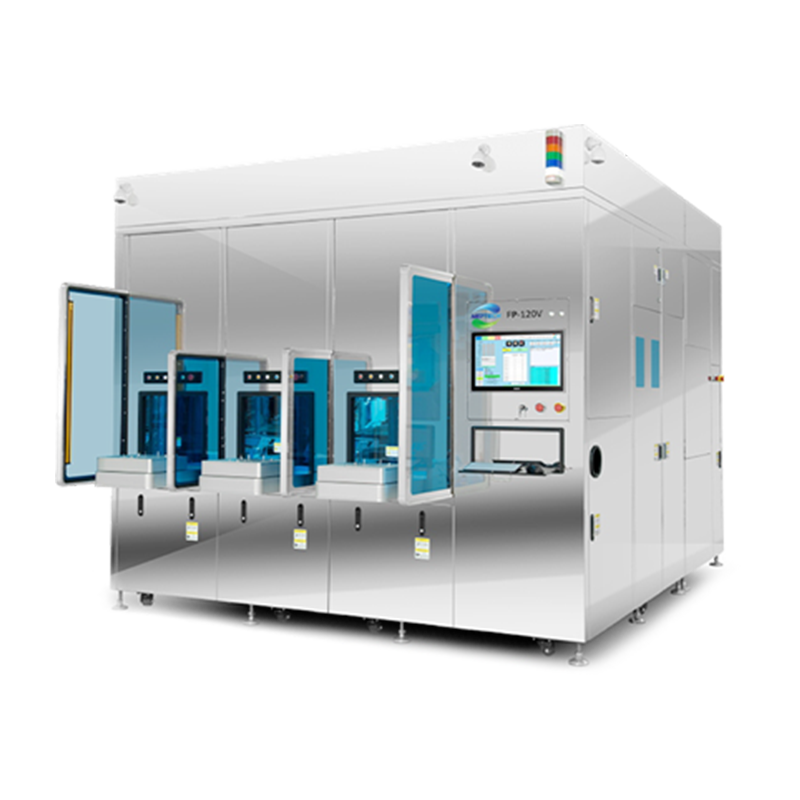

Fully Automatic FOUP Cleaner

-

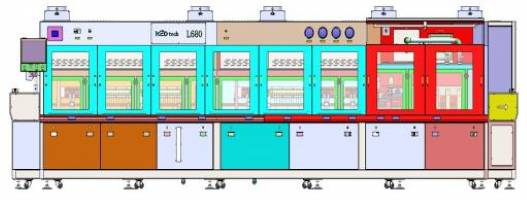

L680 Online Cleaning Machine

-

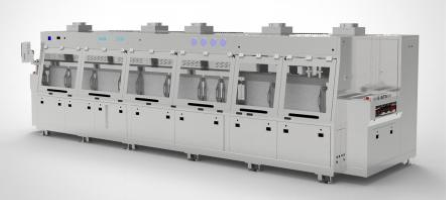

S680 Online Cleaning Machine

-

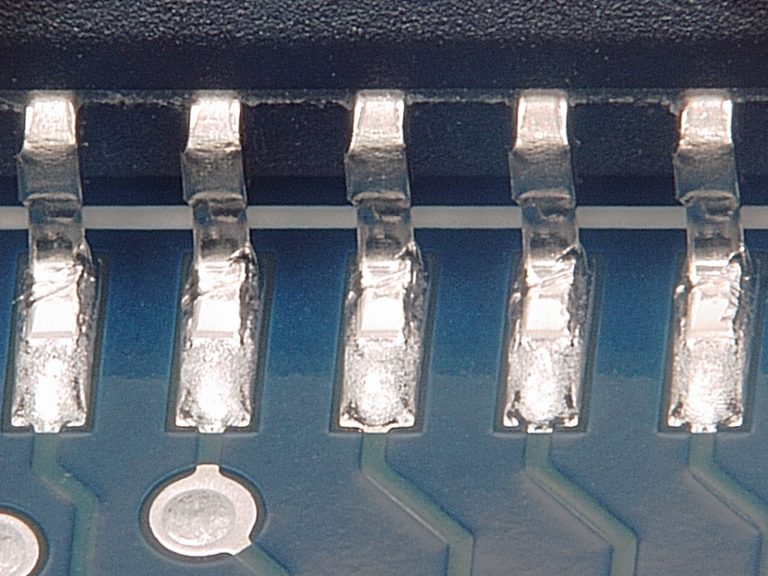

FC-990 Online Cleaner

Learn more

-

KYZEN SLV901

-

AQUANOX 2K100

-

METALNOX M6093

-

KYZEN Booster 20

-

KYZEN CP81

-

MICRONOX MX2127

Learn more

-

GT++

-

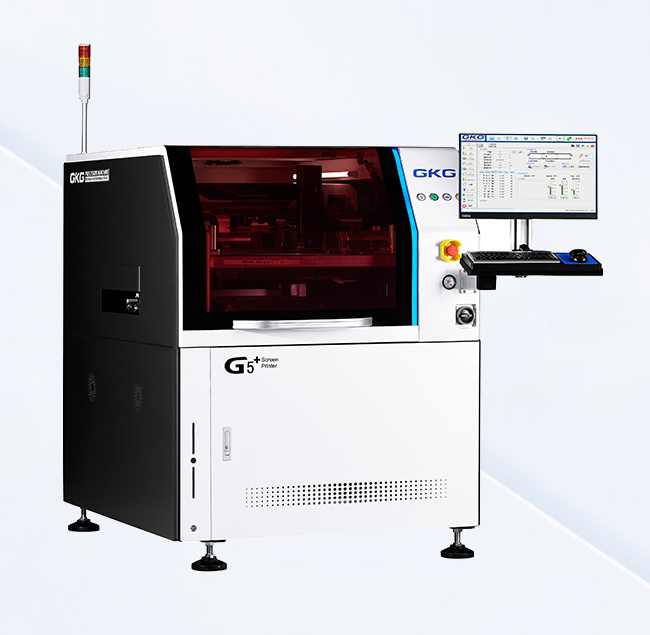

G5+

-

G9+

Learn more

Products

Reflow Soldering and Wave Soldering Equipment

Optical Inspection Equipment AOI/SPI

X-ray Industrial Non-destructive Testing Equipment

SMT Cleaning Equipment

Online PCBA Substrate Cleaning Machine

Cleaning Agent

Precision solder paste printing equipment

Video

-

-

Solutions

-

K&S Surface Mount Machine

Learn more

-

ASM SMT machine

Learn more

-

SMT Production line

Learn more

Solutions

K&S Placement Machine Technical Service and Spare Parts

ASM Placement Machine Technical Service and Spare Parts

SMT Production Line Technical Service and Spare Parts

Video

-

-

About Us

Company Profile

Learn more Shenzhen Minfly Technology Co., Ltd. is an overall solution provider for sales and services in the SMT industry. We have experience and technical expertise in the maintenance and supply of parts for well-known SMT equipment brands such as K&S (Assembleon), ASM, and Ersa, as well as in equipment trading. At the same time, our company collaborates with partners to develop SMT-related automated intelligent products to enhance SMT automation levels and production efficiency.

Shenzhen Minfly Technology Co., Ltd. is an overall solution provider for sales and services in the SMT industry. We have experience and technical expertise in the maintenance and supply of parts for well-known SMT equipment brands such as K&S (Assembleon), ASM, and Ersa, as well as in equipment trading. At the same time, our company collaborates with partners to develop SMT-related automated intelligent products to enhance SMT automation levels and production efficiency.Honors and Qualifications

Learn more Shenzhen Minfly Technology Co., Ltd. is an overall solution provider for sales and services in the SMT industry. We have experience and technical expertise in the maintenance and supply of parts for well-known SMT equipment brands such as K&S (Assembleon), ASM, and Ersa, as well as in equipment trading. At the same time, our company collaborates with partners to develop SMT-related automated intelligent products to enhance SMT automation levels and production efficiency.

Shenzhen Minfly Technology Co., Ltd. is an overall solution provider for sales and services in the SMT industry. We have experience and technical expertise in the maintenance and supply of parts for well-known SMT equipment brands such as K&S (Assembleon), ASM, and Ersa, as well as in equipment trading. At the same time, our company collaborates with partners to develop SMT-related automated intelligent products to enhance SMT automation levels and production efficiency.Development History

Learn more Shenzhen Minfly Technology Co., Ltd. is a comprehensive solution provider for sales and services in the SMT industry. We have experience and technical expertise in the maintenance and supply of parts for well-known SMT equipment brands such as K&S (Assembleon), ASM, and Ersa, as well as in equipment trading. At the same time, our company collaborates with partners to develop SMT-related automated intelligent products to enhance SMT automation levels and production efficiency.

Shenzhen Minfly Technology Co., Ltd. is a comprehensive solution provider for sales and services in the SMT industry. We have experience and technical expertise in the maintenance and supply of parts for well-known SMT equipment brands such as K&S (Assembleon), ASM, and Ersa, as well as in equipment trading. At the same time, our company collaborates with partners to develop SMT-related automated intelligent products to enhance SMT automation levels and production efficiency.Video

-

News

-

Contact Us